16% ↗

increase

avg. time on site

20% ↗

increase

checkout conversions

15% ↗

increase

dealer logins

Powerflex's previous manufacturing processes meant they had little control over their stock levels and all parts were made to order. NEON created a bespoke production management and stock control system that integrated with their accounts package and e-commerce website to provide an ageless solution to solve this problem and allow for controlled stock holding.

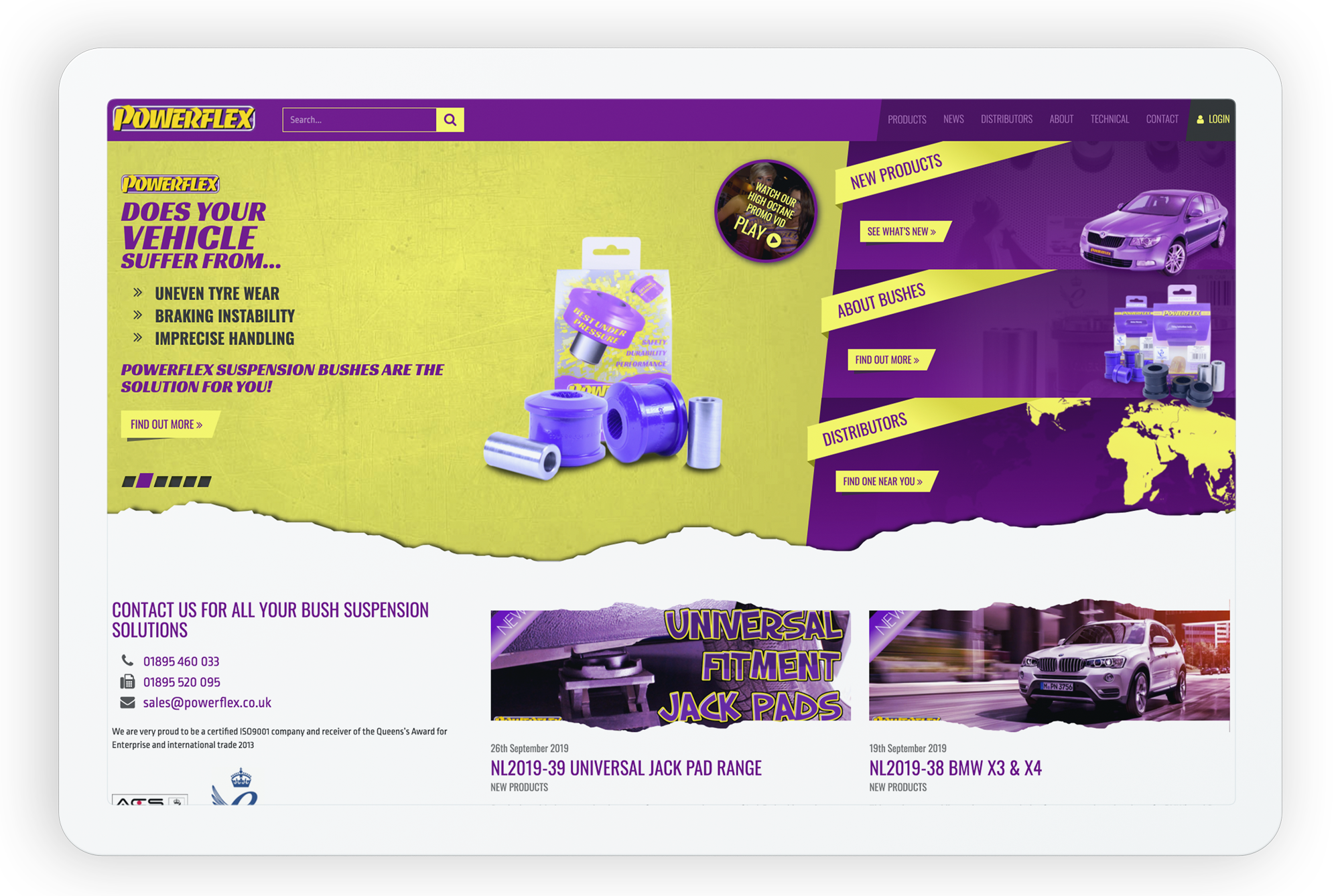

A passion for automotive performance tuning

Powerflex was born out of a passion for performance cars and a desire to offer something different. Standard rubber OEM suspension bushes are notorious for degrading and softening with age and have to be replaced after only a few years’ service. Powerflex saw a gap in the market to introduce an engineered polyurethane replacement solution for popular cars to improve road holding, steering performance and increase longevity. They also offer a motorsport focused option in their ‘Black Series’.

Down, but not out

In 2009, Powerflex were hit by disaster when their premises caught fire destroying pretty much everything in sight.

Undefeated and keen to learn from what had happened, they saw it as an opportunity to restructure and change the way in which they ran their business. A new production management and stock control system was needed to not only speed up the manufacturing of products, but to give greater control over their stock holding. It also provided an accurate record of all stock in case the worst happened again (touch wood it won’t!).

Taking stock

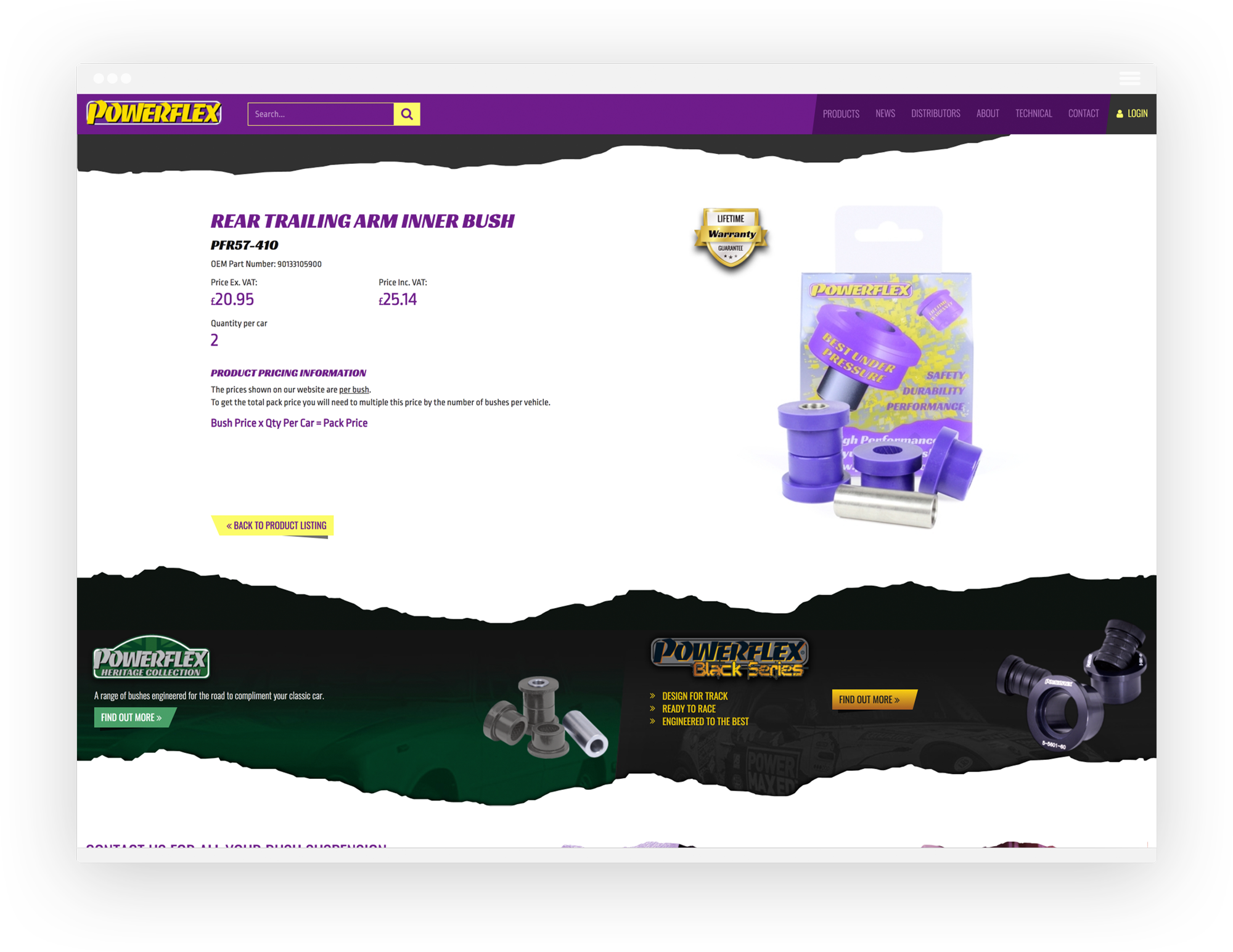

NEON designed and implemented a new bespoke production management and stock control system which records what stock Powerflex have, where it's located and how much is needed based on stock figures and customer order requirements. It suggests which parts will need to be manufactured and when, ensuring customer demand is met.

The solution was a tricky one and creating the exact solution that Powerflex needed would take quite a bit of time. However, once the solution was working well, the effect was dramatic, it allowed Powerflex to slash dispatch times from 2 weeks+ down to just 1-2 days making them one of the fastest and most efficient suppliers in their industry.

Visit their website →

Speak to one of our experts about your project

Call 01245 939 949

In a rush? Why not request a call back at a time convenient for you?